Current issue

Online First

Archive

Instructions for Authors

Guide for Authors

Peer Review Policy

Research Ethics Policy

Crossmark Policy

Ghostwriting and Guest Authorship

Copyright

Open Access Policy

Plagiarism

About the Journal

Aim and Scope

Scientific Board

Publisher

Editorial Board

Indexing in Databases

Personal Data Protection

Repository Policy

Contact

ORIGINAL PAPER

Development and performance evaluation of a hybrid solar dryer using pumpkin fruit. Part 1. Material and Methods

1

Post-harvest Engineering Research Department, Nigerian Stored Products Research Institute, Kano Zonal Office, Nigeria, Nigeria

2

Department of Agricultural and Environmental Engineering, Bayero University, Kano, Nigeria

3

Perishable Crop Research Department, Nigerian Stored Products Research Institute, Kano Zonal Office, Nigeria, Nigeria

4

Research Outreach Department,, Nigerian Stored Products Research Institute, Kano Zonal Office, Nigeria, Nigeria

Submission date: 2025-07-17

Final revision date: 2025-12-14

Acceptance date: 2025-12-18

Online publication date: 2025-12-19

Publication date: 2025-12-19

Corresponding author

Jude Joel

Post-harvest Engineering Research Department, Nigerian Stored Products Research Institute, Kano Zonal Office, Nigeria, Nigeria

Post-harvest Engineering Research Department, Nigerian Stored Products Research Institute, Kano Zonal Office, Nigeria, Nigeria

Journal of Research and Applications in Agricultural Engineering 2025;70(2):39-46

KEYWORDS

TOPICS

ABSTRACT

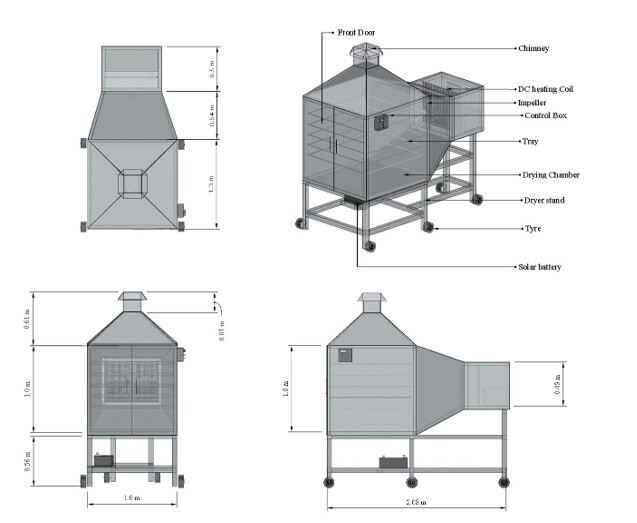

The first part of our research describes the methodology for the development of a hybrid dryer and presents the methods of the study along with the general results obtained. The study presents the design, development, and performance evaluation of a hybrid solar dryer for dehydrating pumpkin (Cucurbita moschata) slices. The dryer integrates solar energy with a DC-powered electrical heating coil to ensure uninterrupted drying and stable thermal conditions during periods of low solar radiation. The system comprises a lagged mild-steel drying chamber, five stainless-steel trays, a centrifugal blower, temperature and humidity control sensors, and a solar-battery power arrangement. Engineering design analyses were conducted to determine heat energy requirements, moisture removal needs, airflow capacity, blower sizing, and solar energy specifications. Performance evaluation was carried out on pumpkin slices of 3 mm, 5 mm, and 7 mm thickness, assessing drying rate, moisture reduction, drying efficiency, shrinkage, rehydration behaviour, colour quality, microbial load, and proximate composition. The hybrid dryer demonstrated efficient heat utilization, improved drying uniformity, and enhanced product quality compared with traditional sun-drying. The results indicate that the developed system offers a reliable and energy-efficient solution for reducing post-harvest losses and improving value addition in pumpkin processing.

REFERENCES (27)

1.

Belessiotis V. and Delyannis E.: Solar drying. Solar Energy, 2011, Vol. 85 (8), 1665 – 1691 https://doi.org/10.1016/j.sole....

2.

Kumar R.S.: Open Sun and Greenhouse Drying of Agricultural and Food Products: A Review. International Journal of Engineering Research & Technology (IJERT), March 2014, vol. 3, Issue 3, ISSN: 2278-0181.

3.

Ratnawati L. et al: The effect of the addition of pumpkin and carrot puree on the physicochemical and textural properties of Mocaf biscuit as a complementary food. IOP Conf. Series: Earth and Environmental Science, 2021, vol. 733, 012120, IOP Publishing. doi:10.1088/1755-1315/733/1/012120.

4.

Doymaz ̇I.: Infrared Drying of Sweet Potato (Ipomoea batatas L.) Slices. J. Food Sci. Technol, 2011, 49, 760–766. doi:10.1007/s13197-010-0217-8.

5.

Fudholi A., Sopian K., Bakhtyar V., Gabbasa M., Othman M.Y., Mohd Hafidz Ruslan M.H.: Review of solar drying systems with air based solar collectors in Malaysia. ScienceDirect., 2015, volume 51, 1191-1204. https://doi.org/10.1016/j.rser....

6.

Gursewak Singh, G. S., Sadhna Arora, S. A. & Satish Kumar S. K.: Effect of mechanical drying air conditions on the quality of turmeric powder. Journal of Food Science and Technology (Mysore), 2010, 47(3 PP-New Delhi), 347–350. https://doi.org/10.1007/s13197....

7.

Yadao, P. B. & Jachak S. R.: Study of different Turmeric Curing Processes. Journal of Emerging Technologies and Innovative Research, 2015, https://api.semanticscholar.or....

8.

Sahay K. M. & Singh K. K.: Unit operation of Agricultural processing. Vikas Publishing House Pvt.Ltd, India, 1994.

9.

Mercer D. G.: An Introduction to The Dehydration and Drying of Fruits and Vegetables. Ontario, Canada: Department of Food Science, University of Guelph, 2014.

10.

Ajisegiri E. S. A., Alabadan B. A. and Uche I. K.: Development of an artificial dryer for yam chips. Proceedings of the 7th International Conference and 28th Annual General Meeting of the Nigerian Institution of Agricultural Engineers, ABU, Zaria, 2006, 28, 348.

11.

Eheim J. C., Irtwange S. V. & Obetta S. E.: Design and development of an industrial fruit and vegetable dryer. Research Journal of Applied Science, Engineering and Technology, 2008, 1(2), 44–53.

12.

Suherman S., Susanto E. E., Zardani A. W., Dewi N. H. R. & Hadiyanto H.: Energy–exergy analysis and mathematical modelling of cassava starch drying using a hybrid solar dryer. Cogent Engineering, 2020, 7(1). https://doi.org/10.1080/233119....

13.

Behera D. D., Mohanty R. C. & Mohanty A. M.: Experimental investigation of a hybrid solar dryer for vegetable drying with and without phase change material. Journal of the Brazilian Society of Mechanical Sciences and Engineering, May, 2024, volume 46, article number 303, 0–12. https://doi.org/10.1007/s40430....

14.

Matuam B., Edoun M., Kuitche A. & Zeghmati B.: Experimental evaluation of the thermal performance of dryer airflow configuration. International Journal of Energy Engineering, 2015, 5(4), 80–86. doi:10.5923/j.ijee.20150504.03.

15.

Chen J., Zhou Y., Fang S., Meng Y., Kang X., Xu X. & Zuo X.: Mathematical modeling of hot air-drying kinetics of Momordica charantia slices and their color change. Advance Journal of Food Science and Technology, 2013, 5(9), 1214–1219. https://doi.org/10.19026/ajfst....

16.

Correia A. F. K., Loro A. C., Zanatta S., Spoto M. H. F. & Vieira T. M. F. S.: Effect of temperature, time, and material thickness on the dehydration process of tomato. International Journal of Food Science, 2015, Article ID 970724, 1–7. https://doi.org/10.1155/2015/9....

17.

Cisni F. M., Neethu K. C., Murali S., Delfiya D. S. A. & Ninan G.: Design and development of solar-electrical hybrid dryer and its performance evaluation using shrimps. Biomass Conversion and Biorefinery, 2023, 14, 25343–25356. https://doi.org/10.1007/s13399....

18.

Mohsenin N.N.: Physical properties of plant and animal materials, second ed. Gordon and Breach Science Publishers, New York, 1986.

19.

Patterson J., Kailasam S., Giftson H. & Immaculate J. K.: Effect of drying technologies on the biochemical properties of Stolephorus commersonnii. Food Quality and Safety , July, 2018, 153–158. https://doi.org/10.1093/fqsafe....

20.

Doymaz İ. & İsmail O.: Drying characteristics of sweet cherry. Food and Bioproducts Processing, 2011, 89(1), 31–38. https://doi.org/10.1016/j.fbp.....

21.

Magalhães I. B., Pereira A. S. A. de P., Silva T. A. & Renato N. dos S.: Predicting the higher heating value of microalgae biomass based on proximate and ultimate analysis. Algal Research, 2022, 64, 102677. https://doi.org/10.1016/j.alga....

22.

AOAC: Official Methods of Analysis of AOAC International, 21st Ed., 2019, AOAC, Gaithersburg, MD, USA.

23.

Saka H. K., Ahmad F. U. & Abubakar A. A.: Microbiological quality assessment of ready-to-eat vegetables sold in Yankaba Market, Kano, Kano State, Nigeria. Dutse Journal of Pure and Applied Sciences, 2022, 8(3b), 163–169. https://doi.org/10.4314/dujopa....

24.

Monalisa K, Bhuiyan JA, Islam MZ & Sayem ASM.: Boiling-induced changes in physicochemical, bioactive compounds, color, and texture properties of pumpkin (Cucurbita maxima). Food Science and Technology International, 2019, 26(4), 333–343. https://doi.org/10.1177/108201....

25.

Bechoff A., Westby A., Menya G. & Tomlins K. I.: Effect of pretreatments for retaining total carotenoids in dried and stored orange-fleshed sweet potato chips. Journal of Food Quality, 2011, 34, 259–267. https://api.semanticscholar.or....

26.

Bechoff A.: Original Research Article: Carotenoid stability during storage of yellow gari made from biofortified cassava or with palm oil. Journal of Food Composition and Analysis, volume 44, 2015, Issue June, 36-44. https://doi.org/10.1016/j.jfca....

27.

Crupi P, Milella RA, Antonacci D.: Simultaneous HPLC-DAD-MS (ESI+) determination of structural and geometrical isomers of carotenoids in mature grapes. J Mass Spectrom. 2010, Sep, 45(9), 971-80 https://doi.org/10.1002/jms.17....

Share

RELATED ARTICLE

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.