Current issue

Online First

Archive

Instructions for Authors

Guide for Authors

Peer Review Policy

Research Ethics Policy

Crossmark Policy

Ghostwriting and Guest Authorship

Copyright

Open Access Policy

Plagiarism

About the Journal

Aim and Scope

Scientific Board

Publisher

Editorial Board

Indexing in Databases

Personal Data Protection

Repository Policy

Contact

ORIGINAL PAPER

The influence of vacuum impregnation of apples by green tea with honey and elderflower juice on drying effects and selected quality factors of apple chips

1

Faculty of Life Science and Technology, Wrocław University of Environmental and Life Sciences, Poland

Submission date: 2025-11-07

Final revision date: 2025-12-19

Acceptance date: 2025-12-19

Online publication date: 2025-12-22

Publication date: 2025-12-22

Corresponding author

Marta Pasławska

Faculty of Life Science and Technology, Wrocław University of Environmental and Life Sciences, Norwida 25, 50-375, Wrocław, Poland

Faculty of Life Science and Technology, Wrocław University of Environmental and Life Sciences, Norwida 25, 50-375, Wrocław, Poland

Journal of Research and Applications in Agricultural Engineering 2025;70(2):58-66

KEYWORDS

TOPICS

ABSTRACT

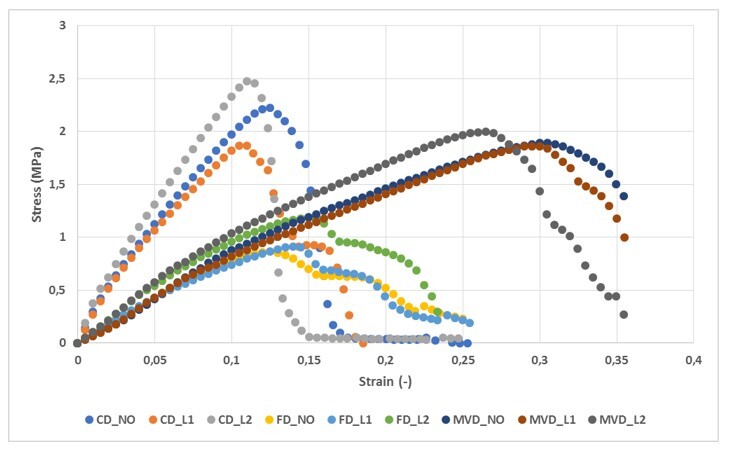

Vacuum impregnation (VI) was applied to Jonagold apple slices using green tea infusion with honey (L1) and green tea with honey and elderflower juice (L2). Samples were dried by convective (CD), microwave–vacuum (MVD) and freeze drying (FD), followed by determinations of dry matter, water activity, colour parameters (L*, a*, b*), tensile properties and drying kinetics. VI slightly increased dry matter and reduced water activity in fresh slices; all dried variants reached low moisture content (9.65–13.31%) and low water activity (0.19-0.35), ensuring shelf stability. VI-modified apple chips showed higher redness and favorable colour characteristics than no pretreated. Tensile tests revealed that drying method strongly affected mechanical response at rupture: CD samples were stiff and strong but brittle, FD samples exhibited low strength and energy absorption, whereas MVD samples combined moderate stiffness with markedly higher deformation capacity and rupture work density, indicating enhanced mechanical resilience. In conclusion, VI with green tea, honey and elderflower is a promising pretreatment method to obtain stable, attractive apple chips.

REFERENCES (20)

1.

Tiwari P., Joshi A., Thakur M.: Vacuum impregnation – a novel nondestructive technique for the development of functional foods. In: Emerging Technologies in Food Science, 2020, 3, 187–199. DOI: 10.1007/978-981-15-2556-8_16.

2.

Corrêa J.L.G., Pereira L.M., Vieira G.S., Hubinger M.D.: Mass transfer kinetics of pulsed vacuum osmotic dehydration of guavas. Journal of Food Engineering, 2010, 96, 498–504. DOI: 10.1016/j.jfoodeng.2009.08.032.

3.

Panarese V., Dejmek P., Rocculi P., Gomez-Galindo F.: Microscopic studies providing insight into the mechanisms of mass transfer in vacuum impregnation. Innovative Food Science & Emerging Technologies, 2013, 18, 169–176. https://doi.org/10.1016/j.ifse....

4.

Fito P.: Modelling of vacuum osmotic dehydration of food. Journal of Food Engineering, 1994, 22, 313–328. DOI: 10.1016/0260-8774(94)90040-X.

5.

Zhao Y., Xie J.: Practical applications of vacuum impregnation in fruit and vegetable processing. Trends in Food Science & Technology, 2004, 15, 434–451. DOI: 10.1016/j.tifs.2004.01.008.

6.

de Lima M.M., Tribuzi G., de Souza J.A.R., de Souza I.G., Laurindo J.B., Carciofi,B.A.M.: Vacuum impregnation and drying of calcium-fortified pineapple snacks. LWT – Food Science and Technology, 2016, 72, 501–509. https://doi.org/10.1016/j.lwt.....

7.

Contreras C., Martin M.E., Martinez-Navarrete N., Chiralt A.: Effect of vacuum impregnation and microwave application on structural changes occurring during air-drying of apple. LWT – Food Science and Technology, 2005, 38, 471–477. DOI: 10.1016/j.lwt.2004.06.017.

8.

Koc B., Eren I., Ertekin F.K.: Modelling bulk density, porosity and shrinkage of quince during drying: the effect of drying method. Journal of Food Engineering, 2008, 85, 340–349. DOI: 10.1016/j.jfoodeng.2007.07.029.

9.

Kręcisz M, Klemens M, Kolniak-Ostek J, Stępień B, Combrzyński M, Latański A. Antioxidant Capacity, Volatile Profile, and Physical Properties Changes of Kohlrabi Treated with Onion and Beetroot Juices Using Vacuum Impregnation Process. Molecules. 2025; 30(17):3563. https://doi.org/10.3390/molecu....

10.

Pasławska M., Nawirska-Olszańska A., Stępień B., Klim A.: The influence of vacuum impregnation on nutritional properties of fluidized-bed dried kale (Brassica oleracea L. var. Acephala) leaves. Molecules, 2018, 23(11), 2764. DOI: 10.3390/molecules23112764.

11.

Jałoszyński K., Szarycz M., Jarosz B.: Wpływ suszenia konwekcyjnego i mikrofalowo-podciśnieniowego na zachowanie związków aromatycznych w pietruszce naciowej (in Polish). Agricultural Eng, 2006, 10(12 (87), Wrocław, s. 209-215.

12.

Jałoszyński K., Szarycz M., Surma M., Stępień B., Pasławska M.: Analiza suszenia mikrofalowo-próżniowego owoców róży dzikiej (in Polish). Agricultural Eng, 2010, 14, Wrocław, s. 223-228.

13.

ASAE Standard: Moisture content content measurement – Grain and seeds. ASAE S361.1, 1986.

14.

Kręcisz M., Stępień B., Pasławska M., Popłoński J., Dulak K.: Physicochemical and quality properties of dried courgette slices: impact of vacuum impregnation and drying methods. Molecules, 2021, 26(15), 4597. DOI: 10.3390/molecules26154597.

15.

Sutar P.P., Prasad S.: Modeling microwave vacuum drying kinetics and moisture content content diffusivity of carrot slices. Drying Technology, 2007, 25, 1695–1702. DOI: 10.1080/07373930701590956.

16.

Adiyaman P., Kanchana S., Mahendran P.P.: Development and stability of bio-food colour from beetroot by spray drying. Carpathian Journal of Food Science and Technology, 2012, 4(2), 63–73.

17.

Stropek Z., Gołacki K.: Method applied to compare stress relaxation curves for various plant materials (in Polish). Agricultural Engineering, 2006, 12, 473–479.

18.

Wiktor A., Łuczywek K., Witrowa-Rajchert D., Hankus M., Królikowski K.: Mathematical modeling of microwave-assisted convective drying of oregano leaves. Advances of Agricultural Sciences: Problems and Issues, 2013, 573, 61–73.

19.

Pasławska M., Stępień B., Nawirska-Olszańska A., Maślankowski R., Rydzak L.: Effect of vacuum impregnation on drying kinetics and selected quality factors of apple cubes. International Journal of Food Engineering, 2017, 13(1), 1–16. DOI: 10.1515/ijfe-2016-0309.

20.

Blanda G., Cerretani L., Bendini A., Cardinali A., Scarpellini A., Lercker G.: Effect of vacuum impregnation on the phenolic content of Granny Smith and Stark Delicious frozen apples. European Food Research and Technology, 2008, 226, 1229–1237. DOI: 10.1007/s00217-007-0643-9.

Share

RELATED ARTICLE

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.