Current issue

Online First

Archive

Instructions for Authors

Guide for Authors

Peer Review Policy

Research Ethics Policy

Crossmark Policy

Ghostwriting and Guest Authorship

Copyright

Open Access Policy

Plagiarism

About the Journal

Aim and Scope

Scientific Board

Publisher

Editorial Board

Indexing in Databases

Personal Data Protection

Repository Policy

Contact

ORIGINAL PAPER

Mechanical properties of Chopin apple cultivar depending on their stage of ripening

1

Department of Engineering Fundamentals, Institute of Agricultural Engineering, Wrocław University of Environmental and Life Sciences, Poland

Submission date: 2025-10-28

Final revision date: 2025-12-09

Acceptance date: 2025-12-12

Online publication date: 2025-12-22

Publication date: 2025-12-22

Corresponding author

Monika Słupska

Department of Engineering Fundamentals, Institute of Agricultural Engineering, Wrocław University of Environmental and Life Sciences, Chełmońskiego 37, 51-630, Wroclaw, Poland

Department of Engineering Fundamentals, Institute of Agricultural Engineering, Wrocław University of Environmental and Life Sciences, Chełmońskiego 37, 51-630, Wroclaw, Poland

Journal of Research and Applications in Agricultural Engineering 2025;70(2):47-57

KEYWORDS

Apple tissue biomechanicsNon-destructive bruise evaluationFinite element modeling of soft biological materialsRipeness-dependent mechanical propertiesMicro-CT in food texture analysis

TOPICS

ABSTRACT

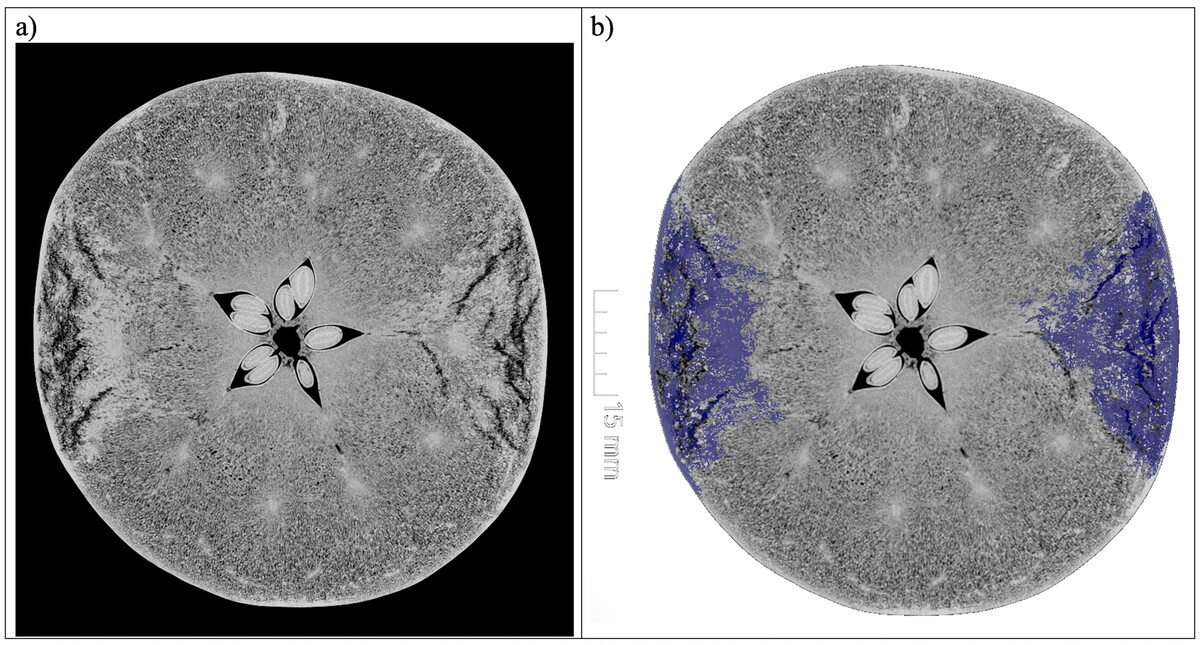

Most available studies on the mechanical properties of apples lack the comprehensive results needed for the construction and validation of static FEM models. Researchers typically focus on either the flesh and epidermis or the whole fruit, often overlooking the maturity stage of the examined apples. They usually report only firmness or the starch index as indicators of maturity. Furthermore, many studies use store-bought apples, which is impractical for industrial applications since this fruit has already undergone various treatments before reaching the shelf. This article aims to determine the mechanical properties of apples necessary for constructing static FEM models that are both adequate and useful for the industry. The new Polish apple variety, Chopin, was selected as the research material. The study was conducted for three stages of apple maturity: development, ripening, and senescence. Mechanical properties of the flesh and skin were determined as material data for FEM models. Force-displacement curves and pressure-force functions were examined for future model validation. Using micro-computed tomography, the bruise volumes of fruit subjected to 20%, 50%, and 80% of the destructive force were determined. Significant differences were found between apples in the senescence stage and those in the development and ripening stages. Results of Micro-Ct and the results of modified and real compression tests of whole fruit have allowed us to formulate the research hypothesis regarding the influence of flesh cracking (characterized by local drops of force), influencing the bruise visibility and detection.

REFERENCES (35)

1.

] Kistechok A., Wrona D., Krupa T.: Effect of storage conditions on the storability and nutritional value of new polish apples grown in central Poland. Agriculture (Switzerland), 2024, 14, 59. doi:10.3390/agriculture14010059.

2.

Ponder A., Jariené E., Hallmann E.: The effect of storage conditions on the content of molecules in Malus Domestica ‘Chopin’ Cv. and their in vitro antioxidant activity. Molecules, 2022, 27(20), 6979. doi:10.3390/molecules27206979.

3.

Kistechok A., Wrona D., Krupa T.: Quality and nutritional value of ‘Chopin’ and clone ‘JB’ in relation to popular apples growing in Poland. Agriculture (Switzerland), 2022, 12(11), 1876. doi:10.3390/agriculture12111876.

4.

Noiton D.A.M., Alspach, P.A.: Founding clones, inbreeding, coancestry, and status number of modern apple cultivars. J. Amer. Soc. Hort. Sci. , 1996, 121(5):773-782.

5.

Hejnowicz Z.: Anatomia i histogeneza roślin naczyniowych. Wydawnictwo Naukowe PWN, Warszawa, 2002, Vol. 1.

6.

Pratt C.: Apple flower and fruit: morphology and anatomy. Horticultural Reviews, Timber Press, 1988.

7.

Zdunek A., Kozioł A., Cybulska J., Lekka M., Pieczywek P.M.: The stiffening of the cell walls observed during physiological softening of pears. Planta, 2016, 243, 519–529, doi:10.1007/s00425-015-2423-0.

8.

Billy L., Mehinagic E., Royer G., Renard C.M.G.C., Arvisenet G., Prost C., Jourjon F.: Relationship between texture and pectin composition of two apple cultivars during storage. Postharvest Biol Technol, 2008, vol. 47(3). doi:10.1016/j.postharvbio.2007.07.011.

9.

Videcoq P., Barbacci A., Assor C., Magnenet V., Arnould O., Le Gall S., Lahaye M.: Examining the contribution of cell wall polysaccharides to the mechanical properties of apple parenchyma tissue using exogenous enzymes. J Exp Bot, 2017, 68(18), 5137–5146. doi:10.1093/jxb/erx329.

10.

Bich L., Pradeu T., Moreau J.F.: Understanding Multicellularity: The functional organization of the intercellular space. Front Physiol, 2019, 10:1170. doi:10.3389/fphys.2019.01170.

11.

Wei J., Ma F., Shi S., Qi X., Zhu X., Yuan J.: Changes and postharvest regulation of activity and gene expression of enzymes related to cell wall degradation in ripening apple fruit. Postharvest Biol Technol, 2010, 56, 147–154. doi:10.1016/j.postharvbio.2009.12.003.

12.

Contigiani E. V., Jaramillo-Sánchez G., Castro M.A., Gómez P.L., Alzamora S.M.: Postharvest quality of strawberry fruit (Fragaria x Ananassa Duch cv. Albion) as affected by ozone washing: fungal spoilage, mechanical properties, and structure. Food Bioproc Tech, 2018, 11, 1639–1650. doi:10.1007/s11947-018-2127-0.

13.

Juxia W., Qingliang C., Hongbo L., Yaping L.: Experimental research on mechanical properties of apple peels. Journal of Engineering and Technological Sciences, 2015, 47(6), 688–705. doi:10.5614/j.eng.technol.sci.2015.47.6.8.

14.

Li Z., Thomas C.: Quantitative evaluation of mechanical damage to fresh fruits. Trends Food Sci Technol, 2014, 35, 138–150. doi:10.1016/j.tifs.2013.12.001.

15.

Farkas Cs., Petróczki K., Fenyvesi L.: Method for measuring fruit failure caused by different mechanical loads. Hungarian Agricultural Engineering, 2016, No 29, 51–54. doi:10.17676/hae.2016.29.51.

16.

Mayorga-Martínez A.A., Olvera-Trejo D., Elías-Zúñiga A., Parra-Saldívar R., Chuck-Hernández C.: Non-destructive assessment of guava (Psidium Guajava L.) maturity and firmness based on mechanical vibration response. Food Bioproc Tech, 2016, 9, 1471–1480. doi:10.1007/s11947-016-1736-8.

17.

Fathizadeh Z., Aboonajmi M., Beygi S.R.H.: Nondestructive firmness prediction of apple fruit using acoustic vibration response. Sci Hortic 2020, 262, doi:10.1016/j.scienta.2019.109073.

18.

Fadiji T., Coetzee C., Pathare P., Opara U.L.: Susceptibility to impact damage of apples inside ventilated corrugated paperboard packages: Effects of package design. Postharvest Biol Technol, 2016, 111, 286–296. doi:10.1016/j.postharvbio.2015.09.023.

19.

Stropek Z., Gołacki K.: A new method for measuring impact related bruises in fruits. Postharvest Biol Technol, 2015, 110, 131–139. doi:10.1016/j.postharvbio.2015.07.005.

20.

Diels E., van Dael M., Keresztes J., Vanmaercke S., Verboven P., Nicolai B., Saeys W., Ramon H., Smeets B.: assessment of bruise volumes in apples using X-ray computed tomography. Postharvest Biol Technol, 2017, 128, 24–32. doi:10.1016/j.postharvbio.2017.01.013.

21.

Van De Looverbosch T., Vandenbussche B., Verboven P., Nicolaï B.: Nondestructive high-throughput sugar beet fruit analysis using X-ray CT and deep learning. Comput Electron Agric, 2022, 200. doi:10.1016/j.compag.2022.107228.

22.

Herremans E. Melado-Herreros A. Defraeye T., Verlinden B., Hertog M., Verboven P., Val J., Fernández-Valle M.E., Bongaers E., Estrade P. et al.: Comparison of X-Ray CT and MRI of watercore disorder of different apple cultivars. Postharvest Biol Technol, 2014, 87, 42–50. doi:10.1016/j.postharvbio.2013.08.008.

23.

Wang L.J., Zhang Q., Song H., Wang Z.W.: Mechanical damage of ‘Huangguan’ pear using different packaging under random vibration. Postharvest Biol Technol, 2022, 187. doi:10.1016/j.postharvbio.2022.111847.

24.

Bejaei M., Stanich K., Cliff M.A.: Modelling and classification of apple textural attributes using sensory, instrumental and compositional analyses. Foods, 2021, 10. doi:10.3390/foods10020384.

25.

Stopa R., Szyjewicz D., Komarnicki P., Kuta Ł.: Determining the Resistance to Mechanical Damage of Apples under Impact Loads. Postharvest Biol Technol, 2018, 146, 79–89. doi:10.1016/j.postharvbio.2018.08.016.

26.

Tomala K., Grzęda M., Guzek D., Głąbska D., Gutkowska K.: The effects of preharvest 1-Methylcyclopropene (1-mcp) treatment on the fruit quality parameters of cold-stored ‘Szampion’ cultivar apples. Agriculture (Switzerland), 2020, 10. doi:10.3390/agriculture10030080.

27.

Pijanowski E., Mrożewski S., Horubała A., Jarczyk A.: Technologia produktów owocowych i warzywnych. PWRiL: Warszawa, 1973.

28.

Słupska M., Stopa R., Figiel A.: Finite element modeling of apple tissue mechanics: a comparative study of elastic and elastoplastic behavior across ripening stages. J Food Eng, 2026, 402, 112696. doi:10.1016/j.jfoodeng.2025.112696.

29.

Sawicka M., Latocha P., Łata B.: Peel to flesh bioactive compounds ratio affect apple antioxidant potential and cultivar functional properties. Agriculture (Switzerland), 2023, 13. doi:10.3390/agriculture13020478.

30.

Przybyłko S., Kowalczyk W., Wrona D.: Article the effect of mycorrhizal fungi and PGPR on tree nutritional status and growth in organic apple production. Agronomy, 2021, 11. doi:10.3390/agronomy11071402.

31.

Ji W., Qian Z., Xu B., Tang W., Li J., Zhao D.: Grasping damage analysis of apple by end-effector in harvesting robot. J Food Process Eng, 2017, 40. doi:10.1111/jfpe.12589.

32.

Jia W., Zhang Y., Lian J., Zheng Y., Zhao D., Li C.: Apple harvesting robot under information technology: a review. Int J Adv Robot Syst, 2020, 17.

33.

Stopa R.: Modelowanie deformacji korzenia marchwi w warunkach obciążeń skupionych metodą elementów skończonych. Monografia. Wydawnictwo Uniwersytetu Przyrodniczego we Wrocławiu, Wrocław, 2010.

34.

Murase H., Merva G.E., Segerlind L.J.: Variation of young’s modulus of potato as a function of water potential. American Society of Agricultural and Biological Engineers, 1980, Vol. 23, Iss: 3, 794-0796.

35.

Słupska M., Stopa R., Figiel A.: Ripening stage in mechanical properties of Chopin apples for static FEM model construction. Preprint at: https://www.preprints.org/manu... (2024).

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.