Current issue

Online First

Archive

Instructions for Authors

Guide for Authors

Peer Review Policy

Research Ethics Policy

Crossmark Policy

Ghostwriting and Guest Authorship

Copyright

Open Access Policy

Plagiarism

About the Journal

Aim and Scope

Scientific Board

Publisher

Editorial Board

Indexing in Databases

Personal Data Protection

Repository Policy

Contact

ORIGINAL PAPER

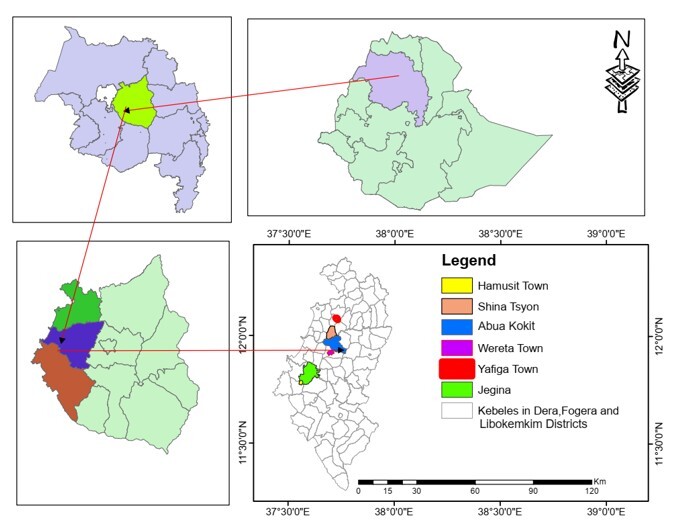

The Current Status and Prospects of the Rice Processing Sector in the Fogera Plain, Northwestern Ethiopia: A Comprehensive Overview and Analysis

1

Department of Agricultural Engineering Research, Ethiopian Institute of Agricultural Research, Fogera National Rice Research, and Training Center, Ethiopia

2

Japan International Cooperation Agency (JICA), EthioRice2 Expert (Agricultural Machinery), Ethiopia

These authors had equal contribution to this work

Submission date: 2025-07-28

Final revision date: 2025-12-10

Acceptance date: 2025-12-10

Online publication date: 2026-01-09

Corresponding author

Dessye Belay Tikuneh

Department of Agricultural Engineering Research, Ethiopian Institute of Agricultural Research, Fogera National Rice Research, and Training Center, P.O. Box: 1937, Bahir Dar, Ethiopia, 6000, Bahir Dar, Ethiopia, Ethiopia

Department of Agricultural Engineering Research, Ethiopian Institute of Agricultural Research, Fogera National Rice Research, and Training Center, P.O. Box: 1937, Bahir Dar, Ethiopia, 6000, Bahir Dar, Ethiopia, Ethiopia

KEYWORDS

TOPICS

ABSTRACT

Ethiopia’s rice production has grown steadily since the 1970s, reaching 268,224 tons in 2020/2021. The Fogera Plain, a major rice-producing region, has strong potential for rice-processing expansion but faces challenges in grain quality, competitiveness, and supply chain efficiency. Rice processing adds value, supports incomes and employment, and strengthens rural economies. This study analyzes the structure, performance, and constraints of the Fogera Plain rice-processing sector, focusing on milling technologies, market dynamics, and operational challenges. Data on machine distribution, processing capacity, technological adoption, and value-chain factors were used to assess milling efficiency and its implications for producers and processors. N90 and NX110 mills dominate the sector (42.64% and 18.60%). Between 1998 and 2023, an average of 6.15 new machines were installed annually, reflecting a 5.25% mean growth. One-pass Engelberg machines account for 75.97% of mills, followed by two-pass SB series (23.25%) and multilevel machines (0.78%). Poor maintenance and limited processing knowledge reduce efficiency, increase breakage, energy use, processing time, and costs, and lower market value. Farmers face high transport costs and limited market access, while processors often act as buyers and traders. Milling is concentrated November–February, and maintaining optimal paddy moisture (12–16%), skilled labor, and efficient machinery is critical. The sector has strong growth potential but is constrained by outdated technology, quality control issues, and supply chain inefficiencies. Enhancing competitiveness requires policy support, strengthened cooperatives, post-harvest management, and educational programs. Premium rice production offers higher returns, but adoption may remain limited without targeted interventions.

REFERENCES (24)

1.

Yemane A.: Determinants of adoption of upland rice varieties in Fogera district, South Gondar, Ethiopia. Journal of Agricultural Extension and Rural Development, 2014. 8(12), 332-338. Available: https://academicjournals.org/j....

2.

Ministry of Agriculture and Rural Development (MoARD). National Rice Research and Development Strategy of Ethiopia. The Federal Democratic Republic of Ethiopia, Ministry of Agriculture and Rural Development, 2010, 48. AU Library, Available: https://library.au.int/nationa....

3.

CSS (Ethiopia Statistics Service). Report on crop and livestock product utilization (Private peasant holdings, Meher season). 2021, Volume VII. Statistical Bulletin 588. In Volume VII Report (Vol. 2, Issue January 2021). Available: https://ess.gov.et/wp-content/....

4.

Tadesse T.: History, current status, and future directions of rice research in Ethiopia. Journal of Emerging Technologies and Innovative Research (JETIR), 2020, 7(2), 767–774. Available at: https://www.jetir.org/papers/J....

5.

Assaye A., Habte E., Sakurai S.: Adoption of improved rice technologies in major rice producing areas of Ethiopia: a multivariate probit approach. Agriculture and Food Security, 2023, 12(1), 1–19. Available at: https://doi.org/10.1186/s40066....

6.

Alemu D., Tesfaye A., Assaye A., Addis D., Tadesse T., Thompson J.: A historical analysis of rice commercialization in Ethiopia: the case of the Fogera Plain. APRA Working Paper, 2018, 18, Future Agricultures Consortium. Available at: https://hdl.handle.net/20.500.....

7.

Assaye A., Alemu D.: Enhancing production of quality rice in Ethiopia: dis/incentives for rice processors. APRA Policy Brief, 2020, 22, Brighton: Future Agricultures Consortium. Available at: https://hdl.handle.net/20.500.....

8.

Ministry of Agriculture (MoA). National Rice Development Strategy-II, 2020–2030. Ministry of Agriculture, 2020, pp. 1–53. Available at: https://riceforafrica.net/wp-c....

9.

Marouzé C., Fliedel G., Thaunay P., and Cruz J. F.: Designing a Fonio Mill. Screening an operating principle and its validation. Agricultural Mechanization in Asia, Africa, and Latin America, 2008, 39(3). Available at: https://www.shin-norin.co.jp/e....

10.

Worku G.: Shrinkage and carbon stock in Wetlands of Fogera Plain, North West Ethiopia. British Journal of Environmental Sciences, 2014, 2(4), 41–50. Retrieved from https://eajournals.org/wp-cont....

11.

Alemu D. & Thompson J.: The emerging importance of rice as a strategic crop in Ethiopia (APRA Working Paper 44). Future Agricultures Consortium, 2020. Retrieved from: https://doi.org/10.19088/apra.....

12.

Taherdoost H.: Determining sample size; how to calculate survey sample size. International Journal of Economics and Management Systems, 2017, 2. Available at: https://ssrn.com/abstract=3224....

13.

Sarkar T., Lee H.-S., Hossen M., Rahman M., Siddiquee M., and Mamun M. Al.: Development of existing Engelberg Rice Mill for improving milling yield and quality. Eco-Friendly Agril. J., 2018, 11(01), 1–12. Available: https://www.researchgate.net/p....

14.

Hegazy R.: Rice milling situation and technology to replace small-scale old husking mills in Bangladesh. 2016. Retrieved from: https://figshare.com/articles/... or https://doi.org/10.6084/m9.fig..., (Accessed on 20 December 2025).

15.

Alemu D., Isinika A., Odame H., Thompson J.: The role of small-scale processors in supporting agricultural commercialisation among smallholder rice farmers in East Africa: lessons from Ethiopia and Tanzania, APRA Working Paper, 2021, 74, Brighton: Future Agricultures Consortium. https://doi.org/10.19088/APRA.....

16.

Dhankhar P.: Rice milling. IOSR Journal of Engineering, 2014, 4(5), 34–42. Retrieved from: https://iosrjen.org/Papers/vol....

17.

Belay, D., Alebachew, M., Alemayehu, T., Tesfaye, R., & Ageze, M.: Introduction of rice quality-enhancing and loss-reduction technologies in the Fogera Plain. In G. Moges, L. Kebede, D. Alemu, F. Kelemu, & A. Fanta (Eds.), Results of Agricultural Engineering Research 2024: Proceedings of Agricultural Engineering Completed Research Activities, 2024. Ethiopian Institute of Agricultural Research (EIAR), Addis Ababa, Ethiopia. Available: https://www.researchgate.net/p....

18.

IRRI: Rice milling systems (Rice Knowledge Bank). International Rice Research Institute (IRRI), 2013.

19.

Musdalipa and Zain M. M.: The case study examines the efficiency analysis of a mobile rice milling business in Pinrang District, specifically in Marannu Village, Mattirobulu District, Indonesia. Pakistan Journal of Life and Social Sciences, 2022, 20(2), 264–270. Available at: https://doi.org/10.57239/PJLSS....

20.

Tikuneh DB. and W/Senbet LK.: Rice mechanization in Ethiopia: trends, and prospects. INMATEH - Agricultural Engineering, 2013, 69(1), 335–348. Available at: https://doi.org/10.35633/inmat....

21.

Ekimie G.M.: “ከውሃው በላኝ ወደ ውሃ አበላኝ /Kä Wuhaw Bälañ Wädä Wuha abälañ (From Water logged Me to Water nourished Me*): A Historical analysis of rice production on enhancing livelihood in Fogera Woreda, 1970s to 2017,” ERJSSH, 2022, vol. 9, 126–142. Available: https://www.ajol.info/index.ph....

22.

Teamir M.: Rice Processing and Consumption Experiences: Implications for Research in Ethiopia. Advances in Rice Research and Development in Ethiopia, 2019, 199. Available: https://www.researchgate.net/p....

23.

Abebe M.: The contributions and challenges of rice value chain development on the livelihood of small holder rice farmers. (In the case of the Ethiopia Driving Growth Entrepreneurship and Trade (EDGET) project in Fogera and Libokmkem District). Addis Ababa University, Addis Ababa, Ethiopia, 2016. Available at: http://etd.aau.edu.et/handle/1....

24.

FAO (Food and Agriculture Organization of the United Nations). Rice post-harvest operations. FAO Agricultural Services Bulletin, 2016. Available: https://www.fao.org/3/i6030e/i....

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.