Current issue

Online First

Archive

Instructions for Authors

Guide for Authors

Peer Review Policy

Research Ethics Policy

Crossmark Policy

Ghostwriting and Guest Authorship

Copyright

Open Access Policy

Plagiarism

About the Journal

Aim and Scope

Scientific Board

Publisher

Editorial Board

Indexing in Databases

Personal Data Protection

Repository Policy

Contact

ORIGINAL PAPER

Development and performance evaluation of a hybrid solar dryer using

pumpkin fruit. Part 2. Analysis of the drying process and the operation of the equipment used

1

Post-harvest Engineering Research Department, Nigerian Stored Products Research Institute, Kano Zonal Office, Nigeria

2

Department of Agricultural and Environmental Engineering, Bayero University, Kano, Nigeria

3

Perishable Crop Research Department, Nigerian Stored Products Research Institute, Kano Zonal Office, Nigeria

4

Research Outreach Department, Nigerian Stored Products Research Institute, Kano Zonal Office, Nigeria

Submission date: 2025-12-15

Final revision date: 2026-01-28

Acceptance date: 2026-02-04

Online publication date: 2026-02-11

KEYWORDS

TOPICS

ABSTRACT

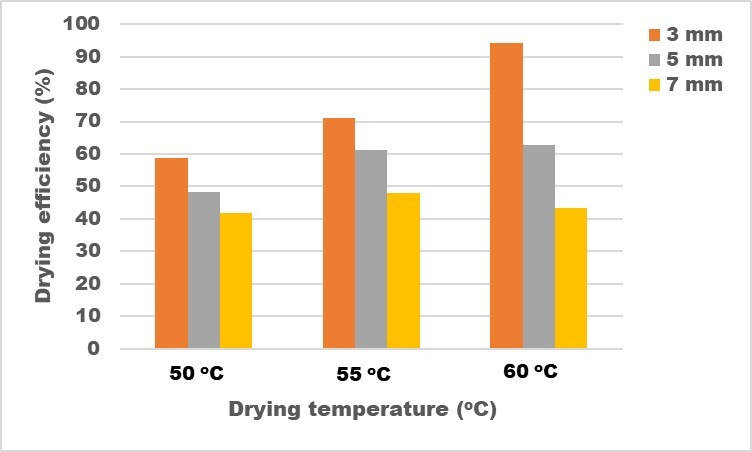

This second part of our work presents the results of analyses of the process of drying pumpkin fruit slices at 50, 55, and 60 °C and slice thicknesses of 3, 5, and 7 mm. The dryer exhibited distinct heating phases under no-load and loaded conditions, with product load slowing the temperature rise. Drying temperature and slice thickness significantly affected drying rate and drying efficiency (p<0.05). The highest drying rate (12–14 kg/h) occurred within the first 2 hours, especially for 3 mm slices at 60 °C. The rate then declined to 2–3 kg/h between 2 and 5 hours and fell below 1 kg/h after 5 hours. Drying efficiency ranged from 42–58% at 50 °C, 47–72% at 55 °C, and increased markedly to 43–94% at 60 °C, with the 3 mm slices at 60 °C achieving the highest efficiency. Energy analysis showed a chamber efficiency of 32.2%. Product quality parameters, including shrinkage, rehydration ratio, proximate composition, microbial load, and colour, varied significantly with drying conditions. Economic analysis indicated a positive net benefit and a payback period of 1 year and 5 months. Overall, the hybrid dryer demonstrated high drying performance, improved energy use, acceptable product quality, and strong economic viability.

REFERENCES (31)

1.

Belessiotis V. & Delyannis E.: Solar drying. Solar Energy, 2011, 85(8), 1665–1691. https://doi.org/10.1016/j.sole....

2.

Ertekin C. & Yaldiz O.: Drying of eggplant and selection of a suitable thin-layer drying model. Journal of Food Engineering, 2004, 63(3), 349–359. https://doi.org/10.1016/j.jfoo....

3.

Doymaz I.: The kinetics of forced convective air-drying of pumpkin slices. Journal of Food Engineering 2007, 79(1), 243 – 248. https://doi.org/10.1016/j.jfoo....

4.

Akpinar E.K. & Bicer Y.: Modelling of the drying of eggplants in thin-layers. International Journal of Food Sci-ence and Technology, 2005, 40(3), 273–281. https://doi.org/10.1111/j.1365....

5.

Midilli A., Kucuk H. & Yapar Z.: A new model for single-layer drying. Drying Technology, 2002, 20(7)(7), 1503–1513. https://doi.org/10.1081/DRT-12....

6.

Joel J., Muhammad A. I., Bala I., Oshadumo D., Saka H. K., Shittu S. K.: Development and performance evalua-tion of a hybrid solar dryer using pumpkin fruit. Part 1. Material and Methods. Journal of Research and Applica-tions in Agricultural Engineering, 2025, 70 (2): 39–46. https://doi.org/10.53502/jraae....

7.

Owolarafe O. K., Bello T. K., Ogunsina B. S., Falana O. B., Adetifa B. O. & Ogunseeyin O.: Performance evalua-tion of a small-scale dryer for agricultural products. AgricEngInt: CIGR Journal, 2021, 23(3), 261.

8.

Cisni F. M., Neethu K. C., Murali S., Delfiya D. S. A. & Ninan G.: Design and development of solar-electrical hy-brid dryer and its performance evaluation using shrimps. Biomass Conversion and Biorefinery, 2023, 14, 25343–25356(2024). https://doi.org/10.1007/s13399....

9.

Doymaz İ.: Drying kinetics, rehydration, and colour characteristics of convective hot-air drying of carrot slices. Heat and Mass Transfer, 2016, 53, 25–35, (2017). https://doi.org/10.1007/s00231....

10.

Kidane H., Farkas I. & Buzás J.: Characterizing agricultural product drying in solar systems using thin layer dry-ing models: a comprehensive review. Discover Food, 2025, 5, 84. https://doi.org/10.1007/s44187....

11.

Gebeyehu S.K., Asemu A. M., Haile S., Kassa M. G.: Influence of temperature and mango pulp thickness on the performance of the batch window refractance dryer. Applied Food Research, 2025, 5(1), 100939. https://doi.org/10.1016/j.afre....

12.

Chinenye N. M.: Effect of drying temperature and drying air velocity on the drying rate and drying constant of cocoa bean. Agricultural Engineering International : The CIGR e-journal, 2009, Xi. 1.

13.

Seifu M., Tola Y. B., Mohammed A., & Astatkie T.: Effect of variety and drying temperature on physicochemical quality, functional property, and sensory acceptability of dried onion powder. Food Science & Nutrition, 2018, March, 1641–1649. https://doi.org/10.1002/fsn3.7....

14.

Abbasi S., Mousavi S. M. & Mohebbi M.: Investigation of changes in physical properties and microstructure, and mathematical modelling of the shrinkage of onion during hot air drying. Iran. Food Sci. Technol. Res. J., 2011, 7, 92-98.

15.

Ojediran J. O., Okonkwo C. E., Adeyi A. J., Adeyi O., Olaniran A. F., George N. E. & Olayanju A. T.: Drying characteristics of yam slices (Dioscorea rotundata) in a convective hot air dryer: application of ANFIS in the pre-diction of drying kinetics. Heliyon, 2020, 6(3), e03555. https://doi.org/10.1016/j.heli....

16.

Wang Z., Sun J., Liao X., Chen F., Wu J. & Hu X.: Mathematical modelling of hot air drying of thin-layer apple pomace. Food Research International, 2007, 40, 39–46. https://doi.org/10.1016/j.food....

17.

Srikanth K. S., Sharanagat V. S., Kumar Y., Bhadra R., Singh L., Nema P. K. & Kumar V.: Convective drying and quality attributes of elephant foot yam (Amorphophallus paeoniifolius). LWT, 2019, 99, 8–16. https://doi.org/10.1016/j.lwt.....

18.

Kowalska H., Marzec A., Kowalska J., Ciurzyńska (Woźnica) A., Samborska K., Bialik M. & Lenart A.: Rehydra-tion properties of the hybrid method dried fruit enriched by natural components. International Agrophysics, 2018, 32, 175–182. https://doi.org/10.1515/intag-....

19.

Özkan Karabacak A., Acoğlu Çeli̇k B., Yolci Omeroglu P. & Çopur Ö.: Microwave pre‐treatment for vacuum drying of orange slices: Drying characteristics, rehydration capacity, and quality properties. Journal of Food Pro-cess Engineering, 2020, 43. https://doi.org/10.1111/jfpe.1....

20.

Miranda M., Rodriguez K. & Vega-Galvez A.: Influence of temperature on the drying kinetics, physicochemical properties, and antioxidant capacity of Aloe Vera (Aloe Barbadensis Miller) gel. Journal of Food Engineering, 2009, 91, 297–304. https://doi.org/10.1016/j.jfoo....

21.

Giang N. T., Hang L. T. T., Loan P. P. & Loan L. T. T.: Effect of Drying Temperature on the Physico-Chemical Properties of Carrot Peel Powder. Pakistan Journal of Agricultural Research, 2024, 37(3), 232–240. https://doi.org/10.17582/journ....

22.

Ihns R., Diamante L. M., Savage G. P. & Vanhanen L.: Effect of temperature on the drying characteristics, colour, antioxidant, and beta-carotene contents of two apricot varieties. International Journal of Food Science and Tech-nology, 2011, 46(2), 275–283. https://doi.org/10.1111/j.1365....

23.

Limpaiboon K., Technology A. & Thammarat N. S.: Effects of Temperature and Slice Thickness on Drying Kinet-ics of Pumpkin Slices. Walailak Journal of Science and Technology (WJST), 8(2) 2011, 8(2), 159–166.

24.

Mota C. L., Luciano C., Dias A., Barroca M. & Guiné R.: Convective drying of onion: Kinetics and nutritional evaluation. Food and Bioproducts Processing - FOOD BIOPROD PROCESS, 2010, 88, 115–123. https://doi.org/10.1016/j.fbp.....

25.

Uribe E., Lemus-Mondaca R., Vega-Gálvez A., Zamorano M., Quispe-Fuentes I., Pasten A. & Di Scala K.: Influ-ence of process temperature on drying kinetics, physicochemical properties, and antioxidant capacity of the olive-waste cake. Food Chemistry, 2014, 147, 170–176. https://doi.org/10.1016/j.food....

26.

Garba Z. N. & Oviosa S.: The effect of different drying methods on the elemental and nutritional composition of Vernonia amygdalina (bitter leaf). Journal of Taibah University for Science, 2019, 13(1), 396–401. https://doi.org/10.1080/165836....

27.

Kim C. J., Kim H. W., Hwang K. E., Song D. H., Ham Y. K., Choi J. H., Kim Y. B. & Choi Y. S.: Effects of Dietary Fiber Extracted from Pumpkin (Cucurbita maxima Duch.) on the Physico-Chemical and Sensory Characteristics of Reduced-Fat Frankfurters. Korean Journal for Food Science of Animal Resources, 2016, 36(3), 309. https://doi.org/10.5851/kosfa.....

28.

CAC/RCP 3: Code of Hygienic Practice for Dried Fruits. Food and Agriculture Organization of the United Na-tions: World Health Organization, November 2006, 1–6.

29.

Wang C., Tian S. & An X.: The effects of drying parameters on drying characteristics, colourimetric differences, and antioxidant components of sliced Chinese jujube. Heat and Mass Transfer, 2022, 58, 1561–1571. https://doi.org/10.1007/s00231....

30.

Vega-Galvez A., Orellana-Palma P., Pasten A., Uribe E., Cortes D. & Carvajal M.: Mild Temperature Conditions Applied to Carrot (Daucus carota L.) Waste Using Different Drying Methods: Effect on the Kinetics and Some Chemical Parameters. Processes, 2025, 13(1), 1–15. https://doi.org/10.3390/pr1301....

31.

Karabulut I., Topcu A., Duran A., Turan S. & Ozturk B.: Effect of hot air drying and sun drying on colour values and β-carotene content of apricot (Prunus armenica L.). LWT - Food Science and Technology, 2007, 40(5), 753–758. https://doi.org/10.1016/j.lwt.....

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.